INDUSTRIAL ELECTRIC FURNACES

- Manufacturing of industrial thermal equipment

- Own design and production facilities

- Modern equipment and machines

ON ELECTRIC FURNACE

Chamber electric furnaces with protective atmospheres

Purpose and application

Chamber electric furnaces, with a protective atmosphere, are used when it is necessary to have a surface without scale on the parts after heat treatment. Products are heated in oxygen-free gases, which minimizes oxidation and decarburization. These electric furnaces, cage type, are used for small-scale production, loading and unloading of blanks is performed horizontally. In chamber furnaces of the SNZ, SNZM brands, it is possible to heat containers or single blanks for hardening, soldering, annealing, normalizing, high tempering. If heat treatment is envisaged up to a temperature of 950 ° C, then it is recommended to use the version with a sealed muffle, type SNZM. For this design, it is recommended to use nitrogen or any other gas as a protective atmosphere required by technology, even hydrogen.

If the heat treatment is carried out at temperatures above 950 ° C, then it is recommended to carry out it without a muffle furnace, type SNZ. For these designs, it is recommended to use only argon, since it does not interact with heaters. In the case of heating up to 900 ° C, nitrogen is allowed.

Description of the design of electric furnaces with heating in a protective atmosphere

An electric furnace, such as SNZ, is performed like a conventional chamber electric furnace, only it has a sealed casing, down conductors are sealed, a sealed door that is pressed through seals. In this design, a protective atmosphere washes over the heaters, lining and localized within the thermal insulation. The absence of metal products in the working area, except for electric heaters, allows these options to be used at higher temperatures than in muffle designs. Heating of electric furnaces SNZ is carried out by spiral or zigzag electric heating elements of the alloy "Kanthal AF".

Electric oven brands SNZM is formed from a chamber furnace in which it is installed sealed muffle. The feed gases are localized within the heating muffle and do not affect heaters, thermocouples, and linings. The muffle design allows virtually any gas to be used, with a significant reduction in shielding gas consumption. Heating is done by spiral or zigzag alloy heaters "Superfechral, or nichrome".

Опции

- Cold Furnace Vacuum System.

- Forced cooling system for muffle, etc.

- Heat treatment according to a given temperature-time schedule with a change in the volume of gas supply. Supply of gas generators.

All atmospheric electric furnaces are equipped with a gas supply unit with indication of pressures, flow rates and the possibility of mixing gases. There is a system oxygen concentration control. The pressure in the working chamber is monitored by a pressure indicator. The exhaust gases are discharged through a special candle. Furnace design allows heat treatment in air.

Control system assembled in a power cabinet or console. The cabinet contains a thermostat, a heat treatment schedule recorder, an oxygen indicator, digital current and voltage indicators. The power section is controlled by thyristor units with a pulse-width modulation function, automatic devices and starters. The front panel of the cabinet contains control buttons, a toggle switch, status indication and alarm lamps. The system ensures the implementation of the necessary technological modes, the blocking of unacceptable (emergency) situations is implemented.

Specifications table

| Designation | Dimensions (width × length × height), mm. | Overall dimensions, mm | power, kWt | Furnace weight, kg |

|---|---|---|---|---|

| СНЗ 4.6.2,6/12 | 600×800×400 | 1460×1500×1920 | 12 | 550 |

| СНЗ 6.8.4/12 | 400×600×260 | 1250×1310×1760 | 16 | 900 |

| СНЗ 8.12.5/12 | 800×1200×500 | 1550×2050×2020 | 40 | 1200 |

| СНЗМ 4.5.3/10 | 400×500×340 | 1660×1530×1980 | 20 | 760 |

| СНЗМ 5,5.8.5/10 | 550×800×490 | 1710×1800×2000 | 30 | 900 |

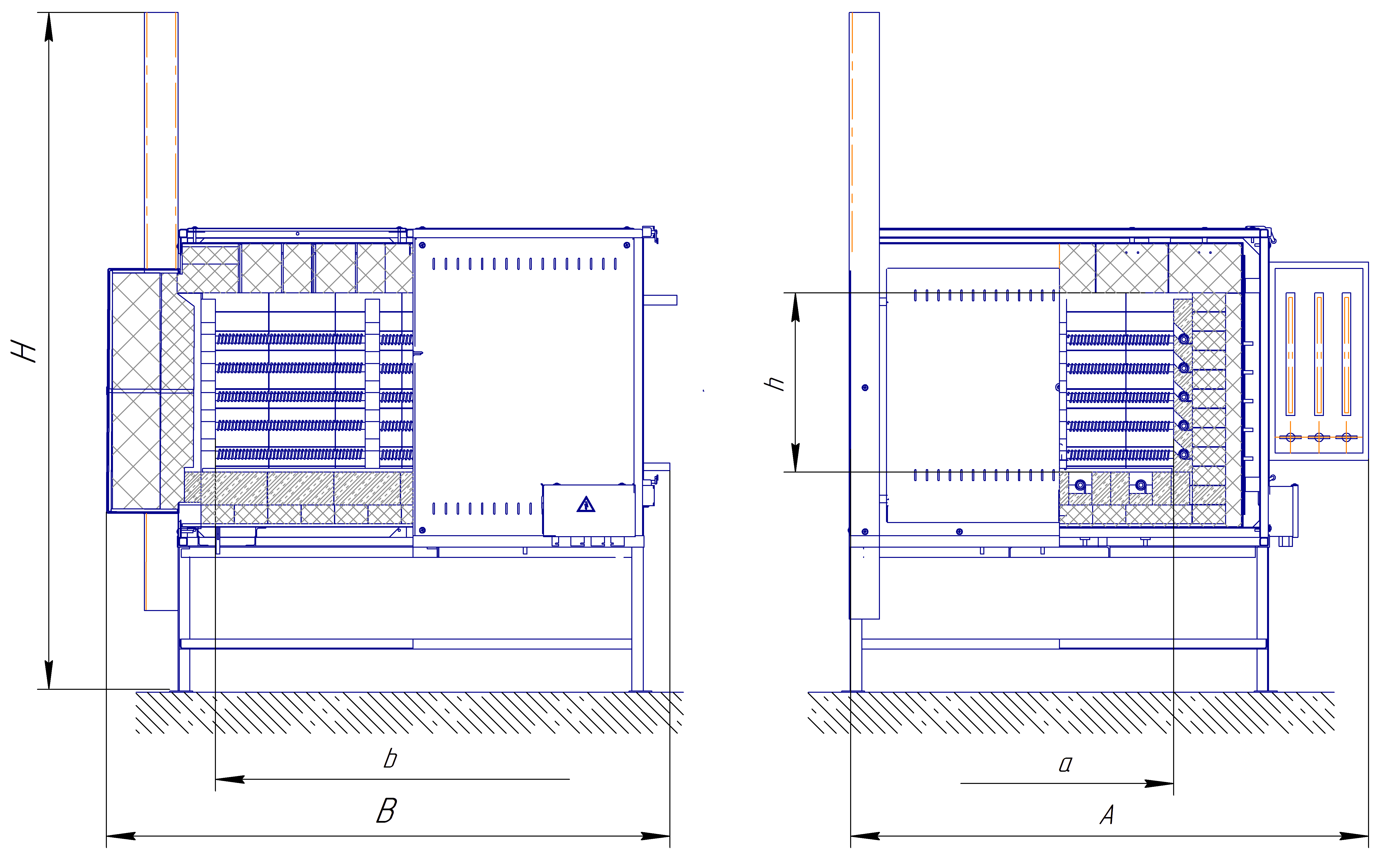

View design sketch

During manufacturing, a high tightness of the working space is ensured, completely excluding the supply of oxygen from the air. An inert lining is installed for the gases used. The sealing of the loading opening and the cover, as well as the down conductors of the heaters, in combination with other measures, ensures that the overpressure in the furnace is maintained at a level of 3 - 5 mm of water column, which excludes air leaks. An individual approach to achieving the required task and a variety of options allows our customers to purchase optimal equipment with high reliability.

An individual approach to achieving the required task and a variety of options allows our customers to purchase optimal equipment with high reliability.

(the territory of OJSC "Ural plant RTI")