INDUSTRIAL ELECTRIC FURNACES

- Manufacturing of industrial thermal equipment

- Own design and production facilities

- Modern equipment and machines

ON ELECTRIC FURNACE

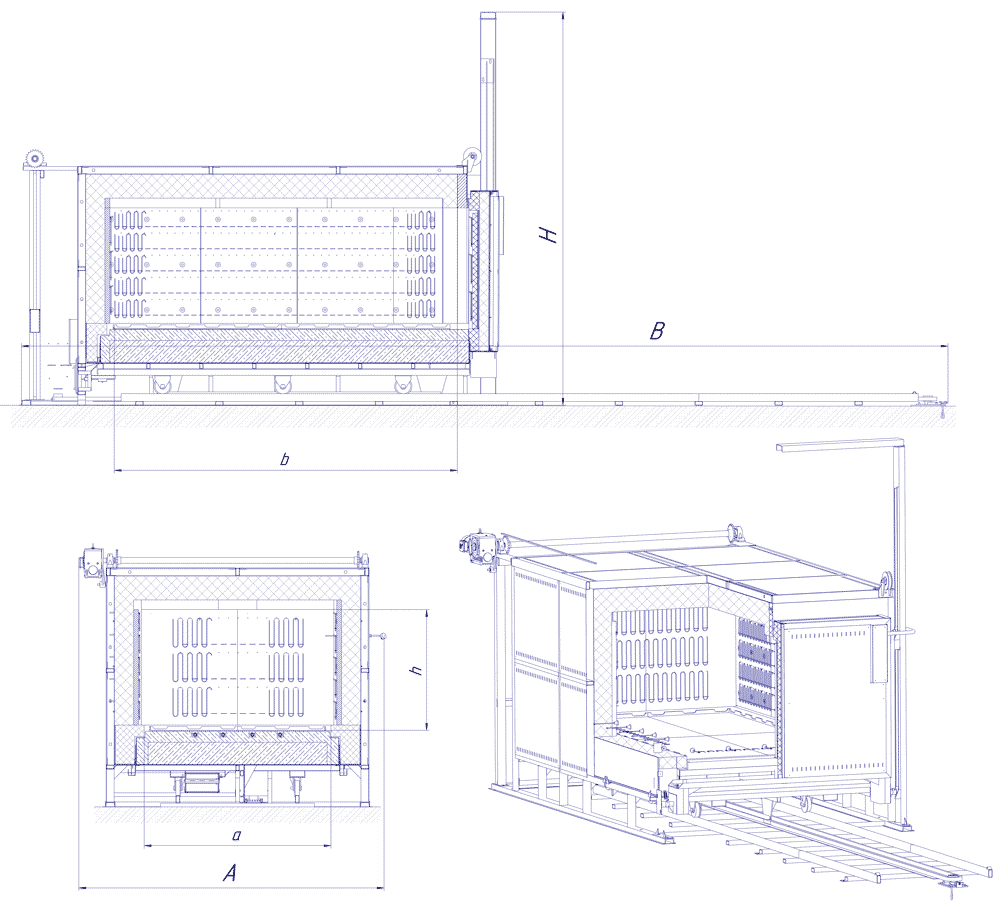

Electric chamber hardening furnaces with bogie hearth

Purpose and application

Chamber hardening electric bogie hearth furnaces are intended for heating billets for hardening, annealing and normalizing. A distinctive feature of these electric furnaces with a roll-out hearth design, which is very convenient when loading and unloading large-sized structures.

Description of construction.

Chamber hardening electric furnaces are assembled on the basis of a steel welded frame, in the form of a rectangular chamber. The frame is lined with fibrous materials from the inside, and heat-insulating and dense refractory bricks under the furnace. As agreed with the Customer lining side walls can be made of fibrous compressed modules, slabs, or brick. The roof of all chamber kilns is assembled from pressed ceramic fiber Z-shaped pressed blocks.

Electric heaters are made in the form of spirals or in the form of zigzags from alloys Eurofehral, Kanthal, nichrome. The heaters are evenly distributed along the walls of the working chamber lining, on the door and on the hearth. Heaters installed on all sides allow for uniform heating of workpieces.

Stove damper rises upward, freeing the loading opening, along the guides or with the help of a coupled mechanism, the movement of which is limited to a horizontal position. Further lifting of the damper is carried out with the help of a paired mechanism along the guides (∏) of the shaped frame by an electromechanical drive.

Electric furnace workspace formed, along the height from the hearth to the roof, along the perimeter of the oven: this is the distance between the side heaters and the rear wall and door heaters.

Roll-out under consists of a welded metal frame, on wheel pairs, in the form of a lined trolley and a set of baking plates. The bottom plate protects the liner from damage during loading. The hearth and heating chamber are compacted through a sand gate or through a clamp with a cord seal. The pod roll-out is mechanized. The movement is carried out along a special rail track. Drive control is displayed on the push-button panel. The rail track is made of steel profiles and is attached to the workshop floor. Stopping the hearth flush with the front frame is ensured by reducing the rolling speed at the end stage and setting the limit switch.

Control system

Bogie hearth furnaces are equipped with a digital temperature control system. Heating control is carried out through powerful thyristor units with PWM function, with current control. Registration and archiving of heat treatment schedules is carried out on the "Termodat" device. The control system provides the necessary interlocks and prevents emergencies, including the opening of automatic circuit breakers when the door is lifted, the permissible temperature is exceeded, the thermocouple breaks, etc. Power and control equipment, including control devices, are installed in an electrical cabinet and a push-button control panel.

Specifications table

| Designation | Working dimensions (d × h) | Gab. dimensions (A × B × H), mm | power, kWt | Furnace weight | Max. loading, t |

|---|---|---|---|---|---|

| СДО 7.12.8/12 | 700×1200×800 | 1600×3600×2200 | 55 | 1250 | 0,8 |

| СДО 8.16.8/12 | 800×1600×800 | 1600×4700×1900 | 75 | 2220 | 1,2 |

| СДО 10.20.10/12 | 1000×2000×1000 | 1850×5800×3400 | 110 | 3000 | 2,5 |

| СДО 12.25.15/12 | 1200×2500×1500 | 2700×6300×4200 | 140 | 4500 | 4 |

| СДО 15.30.15/12 | 1500×3000×1500 | 2900×7100×4200 | 180 | 5800 | 5 |

| СДО 18.40.15/12 | 1800×4000×1500 | 3200×9000×4200 | 250 | 8000 | 7 |

View design sketch

The optimal ratio of dense refractories on the hearth and fibrous thermal insulation along the side walls increases its service life, minimizes heat loss through heat transfer and accumulation. The increased total insulation thickness minimizes heat loss through the walls. Cast hearth plates made of steel no worse than 15Kh23N18L. The use of a direct engagement sprocket mounted on the drive and a rack rigidly mounted on the hearth eliminates jerks and inertial movement during start and stop.

(the territory of OJSC "Ural plant RTI")