Quenching oil, water and water-polymer baths

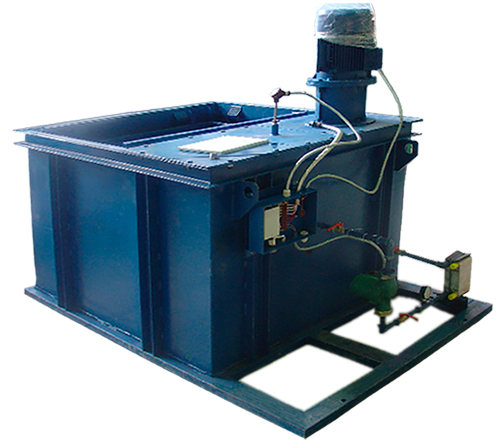

Quenching baths are designed for accelerated cooling of metal products for quenching by immersion in a liquid.

For various steel grades and billet profiles, the optimal cooling media can be oil, water, or a water-polymer solution. Depending on the composition of the coolant, the quenching baths differ in purpose, design and scope of delivery. Regardless of the cooling medium, all bath designs have systems for preheating, cooling and mixing the working medium with the necessary fittings, an indication of the flow pressure and a control system.

Maintaining the set temperature of the liquid is carried out by turning on the electric heating elements built into the tank when the temperature is below the set one, and turning off the heating elements with turning on the pump for supplying liquid to the plate heat exchanger when the temperature is higher than the nominal.

The coolant for supply to the heat exchanger is discussed individually, it can be water or various brands of antifreeze. Coolant cooling system (cooling tower or chiller) available as an option.

The intensity of billet cooling is set on the frequency converter of the impeller rotation drive for the period when the charge is in the liquid and nominally lies in the range of 350-600 rpm. The number of impellers is set depending on the volume of the tank. One impeller, on average, is installed for 2-2.5m3 of quenching liquid.

Differences in configuration

Oil quenching baths (VZM models)

Oil baths must be completed with an inert gas supply pipe, passing above the mirror, but below the lid, a cover, depending on the size of a removable or hinged, onboard suction, a sump for water and a drain valve. An enlarged branch pipe for quick emergency draining into a storage tank. Optionally, a mesh basket is offered for the case of possible spilling (falling out) of small workpieces to the bottom of the tank, an emergency oil drain container.

Water quenching baths (models VVZ)

Baths under water are the simplest in design and configuration, therefore, they are supplied as standard, with a slightly increased power and high heat capacity of water. Baths can be made of the required dimensions, for the Customer's workpieces, including mine designs.

Water-polymer quenching baths (VZP models)

Baths for water-polymer media are analogs of water baths, only additionally equipped with a system for measuring the rate of cooling of the standard in the test solution. In this embodiment, the composition and, accordingly, the cooling capacity can be adjusted, and for this it is necessary to periodically analyze the cooling capacity of the liquid. The control system includes a standard with a thermocouple, a standard heating furnace, a recorder of the standard cooling schedule.

Upon request, we can supply an initial polymer solution for water-polymer hardening, a niodimum magnet in case of searching for accidentally dropped workpieces. Pre-commissioning services are offered.

| Bath designation | Working fluid | Working dimensions, mm (L × W × H) | Gab. dimensions, (lxwxh), mm | Max. loading weight, kg | Installed power, kW |

|---|---|---|---|---|---|

| VZV 7.6.6/0,8 | Water | 700×600×600 | 1400×1000×1000 | 40 | 7 |

| VZV 9.7.7/0,8 | Water | 900×700×700 | 1500×1100×1450 | 60 | 10 |

| VZV 16.12.9/0,8 | Water | 1600×1200×900 | 2300×1600×1600 | 500 | 30 |

| VZV 21.18.15/0,8 | Water | 2100×1800×1500 | 2100×1800×1500 | 950 | 80 |

| VZM 9.7.7/0,6 | Oil | 900×700×700 | 1600×1200×1500 | 50 | 10 |

| VZM 12.9.8/0,6 | Oil | 1200×900×800 | 1900×1400×1600 | 120 | 20 |

| VZM 16.12.15/0,6 | Oil | 1600×1200×1500 | 2300×1600×2100 | 700 | 60 |

| VZP 9.7.7/0,8 | Water-polymer | 900×700×700 | 1500×1100×1450 | 60 | 10 |

| VZP 21.18.15/0,8 | Water-polymer | 2100×1800×1500 | 2100×1800×1500 | 950 | 80 |

(the territory of JSC "Ural plant RTI")