ELECTRIC LABORATORY OVENS

- Manufacturing of laboratory heating equipment

- Own design and production facilities

- Modern equipment and machines

ON ELECTRIC FURNACE

Chamber muffle furnaces PM

Purpose and description

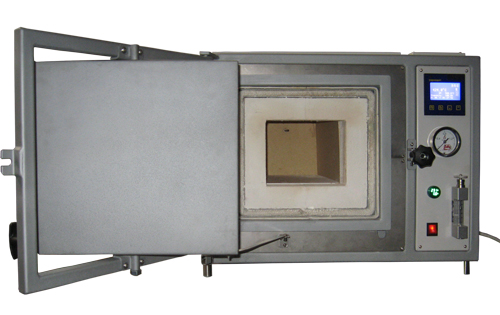

Chamber electric furnaces with a protective atmosphere are a type of chamber muffle electric furnaces, the working space of which is supplied with a protective (oxygen-free) atmosphere. These furnaces are made in a gas-tight design with elements of seals between the door and the chamber, as well as with a gas supply system. Nitrogen or argon can be used as a protective atmosphere. The PKZ furnace design does not provide for the supply of hydrogen-containing gases; for this, special furnaces with metal muffles are used.

Chamber furnaces with a protective atmosphere are used when heating is carried out, for example, for annealing, annealing, calcination, when oxidation of the heated sample or workpiece is not allowed. Also in this oven it is allowed to carry out heat treatment in a normal, oxidizing air atmosphere. For the ceramic muffle, sudden temperature changes are undesirable, e.g. during loading massive cold workpiece into a hot oven. Therefore, muffle electric furnaces, including those with a protective atmosphere, are recommended to be used for annealing, calcination of small metal workpieces or bulk materials in pallets. Depending on the density of the supplied gas, it must be fed to the bottom of the furnace or to the top. The shielding gas supply to the furnace is adjustable rotameter. To reduce the effect of the furnace atmosphere on the heater, all muffle furnaces can be supplied with a forced blowdown option. (option)

In the working space, ceramic flakes are installed as a muffle. A ceramic muffle protects the working area from electric heaters. Heat treatment temperature in muffle furnaces are lower than in PKL furnaces, because the electric heaters are closed in the space between the thermal insulation and the muffle elements.

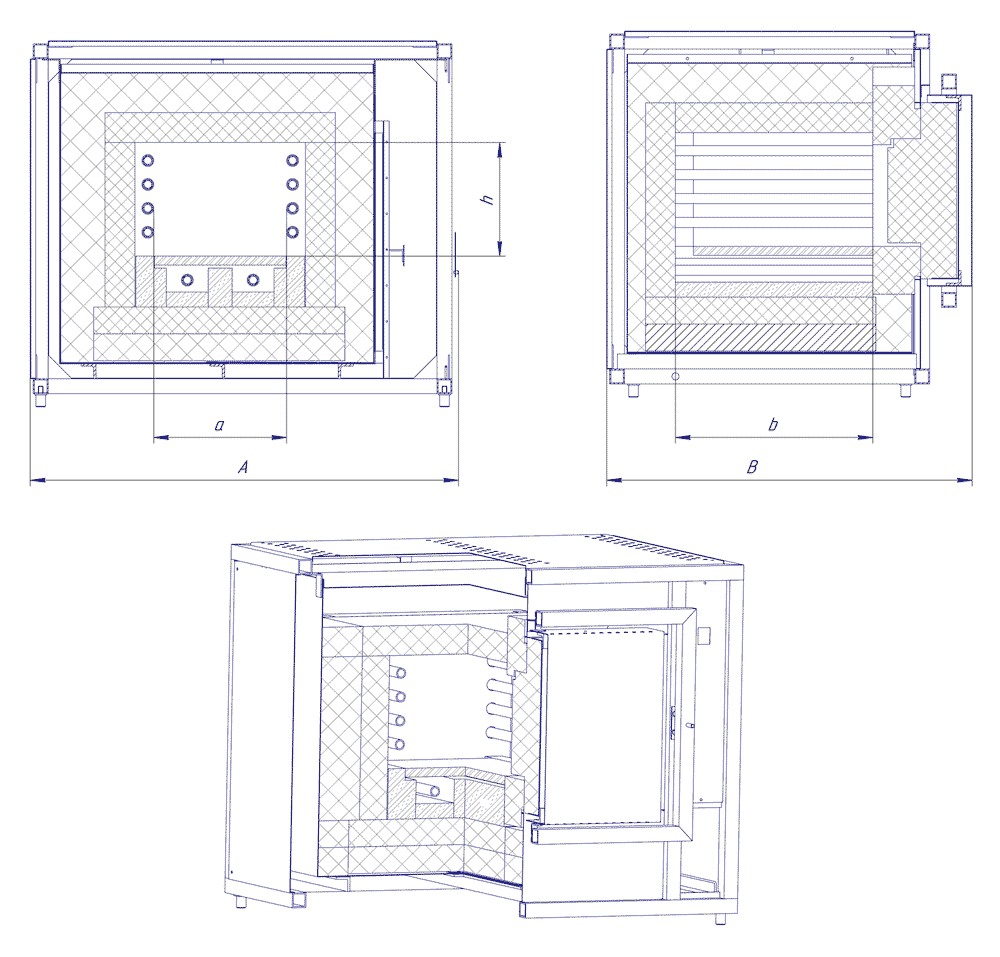

The heat insulation of the furnace is made of modern, high-performance heat-insulating materials. Chamotte fiber boards and flexible ceramic fiber mats are used as thermal insulation. Thermal insulation has a relatively low thermal capacity and heat accumulation. Heating up to maximum temperature will not exceed 80 minutes. Heating of the samples is provided by spiral electric heaters placed on the sides of the working chamber in the space between the lining and the muffle. The hearth spirals are laid into special channels of the hearth lining and covered with a muffle. The spiral heaters are fastened without touching the lining heater and the muffle.

The heating zone of the electric furnace is covered by a lined door with a twin mechanism. When the oven is opened, the door moves to the side, so that the internal heated thermal insulation of the door, when it is opened has always been turned in the direction of the oven, which minimizes the possibility of scalding during loading and unloading.

The thermostat allows you to heat the workpieces at a predetermined temperature and maintains it until the heating is turned off. For more complex research, it is possible to complete the furnace with multistage thermostats. Such a thermostat allows you to set a heating program that takes into account up to 10 stages of heat treatment at different temperatures. Power and control units are mounted in a special compartment of the furnace, on the right side oven or bottom. The supply voltage for laboratory equipment is 220 volts.

Purge chamber, oven stands, exhaust probes, etc. are available as options.

Specifications table

| Designation | Working dimensions (a×b×h) | Gab. size (A × B × H), mm | Heating temperature,° С | power, kWt | Furnace weight |

|---|---|---|---|---|---|

| PKZ 1,0-8 | 180×300×150 | 800×590×610 | 1000 | 2,2 | 50 |

| PKZ 1,0-12 | 200×300×200 | 840×640×730 | 1000 | 3,1 | 60 |

| PKZ 1,2-36 | 300×300×400 | 935×1420×820 | 1200 | 4,8 | 110 |

View design sketch

We offer a wide range of chamber laboratory electric furnaces heated in protective atmospheres for various tasks with an optimal set of functions and capabilities, including those not reflected in this section. A wide assortment and diversified options allows our customers to purchase the optimal equipment for solving problems related to research, with high accuracy and reliability..

(the territory of OJSC "Ural plant RTI")