INDUSTRIAL ELECTRIC FURNACES

- Manufacturing of industrial thermal equipment

- Own design and production facilities

- Modern equipment and machines

ON ELECTRIC FURNACE

Mine hardening electric furnaces

Purpose and application

Shaft hardening electric furnaces are designed for heating, large or medium-sized, piece workpieces or baskets with small workpieces for hardening, annealing or normalization, it is also allowed to carry out high tempering. Radial heaters, as well as zone regulation, allow for quick and even heating of workpieces. Vertical designs take up less workshop space and are convenient when processing long workpieces.

Description of construction

Furnace frame made in the form of a truss sheathed with casings in the form of a well, the internal space, which is lined (lined) with heat-insulating and refractory materials, in such a way that the heat is localized inside the mine, and the outer surfaces of the frame remain cold.

Electric heaters evenly distributed in diameter and height, which forms a uniform temperature field. Versions with a diameter of more than 1 meter are equipped with hearth heaters. Circular heating allows you to evenly heat workpieces, especially long shafts. As an option, elements for fixing the suspended loading equipment can be made in the loading mouth.

Side heaters can be spiral or zigzag precision wire or tape. The material can be iron-chromium-aluminum alloy "Fechral", or "nickel-chromium" alloy. Mostly electric heaters are made in the form of spirals from the Superfechral alloy and are mounted on ceramic tubes with an indent from the walls. Zigzag-style hangs directly on staples and lining protrusions.

The working space forms a screen in the form of a rolled cylinder to protect structures when loading and unloading workpieces. The masonry of the hearth is also covered with a steel sheet. The heating chamber is covered from above by a lined cover. The loading opening is released by a mechanized lifting and rolling of the cover to the side.

Electric furnaces have a lightweight lining, heaters extended from the walls, which makes it possible to increase the efficiency of heat treatment, which is especially noticeable during single-shift operation.

Control system.

Mine electric furnaces in standard design have electronic temperature control with digital display. The current is supplied through powerful thyristors with PWM function and digital indication. To register the temperature regime, there is a registering device of the "Termodat-18" brand. In order to increase the safety of work, all electric furnaces are equipped with interlock switches to remove the voltage when the door is opened. If the thermocouple breaks or if the set value is exceeded by 30 degrees, the protection will work and cut off the voltage supply. The necessary power and control equipment is installed in the control cabinet. The control cabinet and the electric furnace are connected by power and control wires protected by flexible corrugated sleeves.

Specifications table

| Designation | Working dimensions (dia × height) | Overall dimensions, mm | power, kWt | Furnace weight | Nom. production, kg/h |

|---|---|---|---|---|---|

| SSO 6.9/12 | 600×900 | 1500×1850×1700 | 40 | 1000 | 70-80 |

| SSO 8.12/12 | 800×1200 | 1650×2800×2400 | 70 | 1800 | 100-110 |

| SSO 10.15/12 | 1000×1500 | 1800×3500×2800 | 100 | 2500 | 130-150 |

| SSO 10.20/12 | 1000×2000 | 1800×3500×3400 | 130 | 2800 | 150-180 |

| SSO 12.15/12 | 1200×1500 | 1900×2400×2800 | 120 | 3100 | 150-170 |

| SSO 12.20/12 | 1200×2000 | 1900×2400×3400 | 170 | 4000 | 150-170 |

| SSO 15.20/12 | 1500×2000 | 2200×4300×3150 | 190 | 4400 | 190-220 |

| SSO 20.25/12 | 2000×2500 | 2900×5600×4000 | 370 | 7000 | 300-350 |

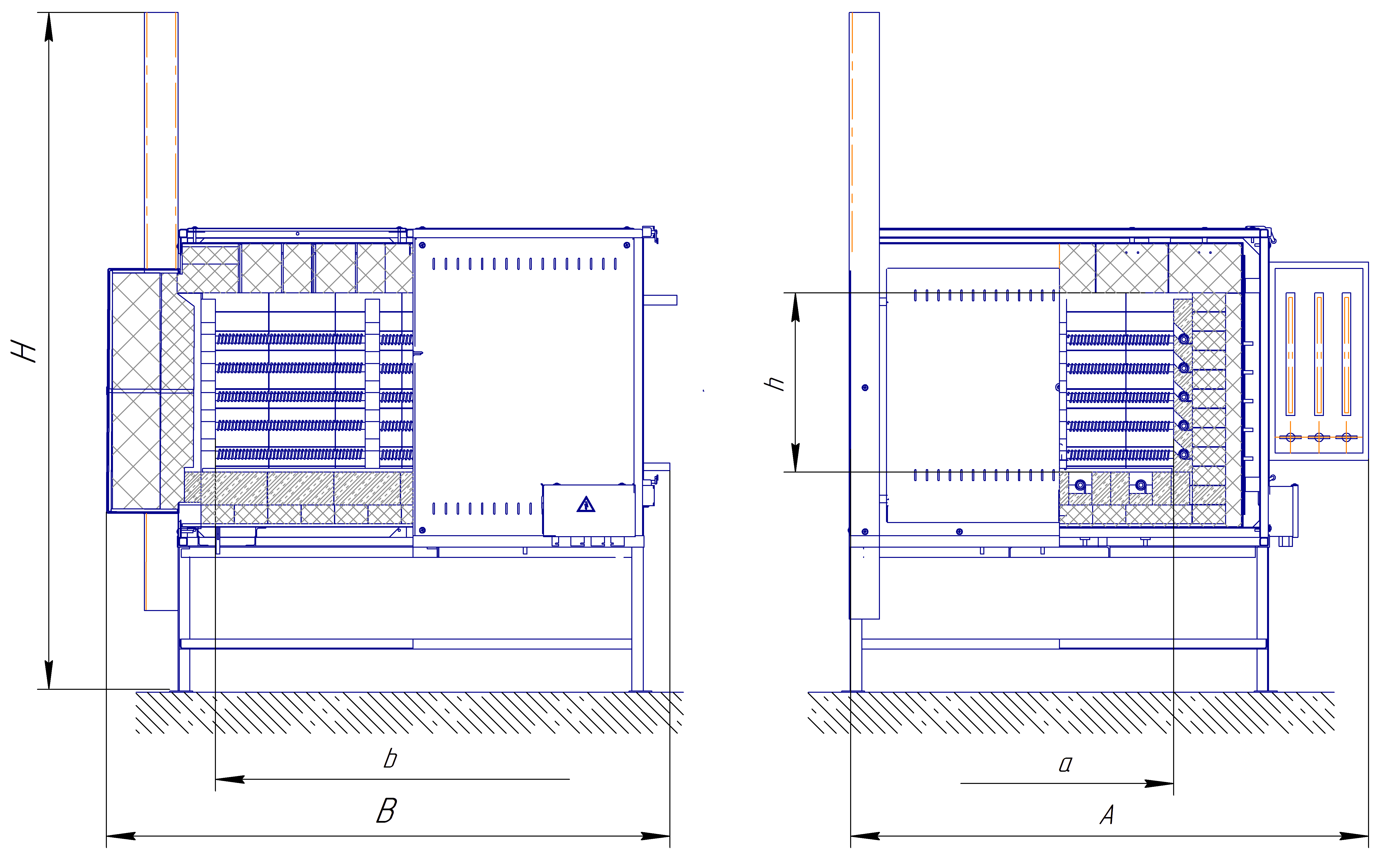

View design sketch

The optimal ratio of dense refractories on the hearth and fibrous thermal insulation along the side walls increases its service life, minimizes heat loss through heat transfer and accumulation. Reduces the time the oven leaves the cold state to the operating mode, etc.). The cylindrical screen protects the workpieces from touching the heaters. High temperature uniformity due to zone temperature control.

(the territory of OJSC "Ural plant RTI")