ROLLER CONVEYORS AND ROLLERS FOR YOUR TASKS AND SIZES

Appointment

The roller conveyor is used to move products or materials that will be stable and will not spill through the roller pitch. And also when the use of tape designs is impossible or impractical. In most cases, these are blanks or containers with flat and flat surfaces. If the surfaces are non-flat, shallow or even loose, then containers can be used as containers.

Rollers are very versatile and capable of moving rectangular containers, boxes, pallets, slabs, rolled metal, lumber, bags of bulk material and much more.

The advantage of roller conveyors over belt conveyors

- They are able to carry significantly large loads without the risk of breaking the working device, this is especially true with a considerable length transportation or increased load.

- Able to change the speed of movement in the desired areas.

- The shape of the barrel can be mirrored to the shape of the product being moved..

- There is no need for periodic replacement of the transport bed, as there is practically no friction.

- There is no technical limitation in the length of the transportation route.

- It is possible to direct flows along a non-straight path, it can even be looped.

- You can split or merge thread branches.

- Significantly longer period of trouble-free operation due to the absence of restrictions in the resource of executive devices.

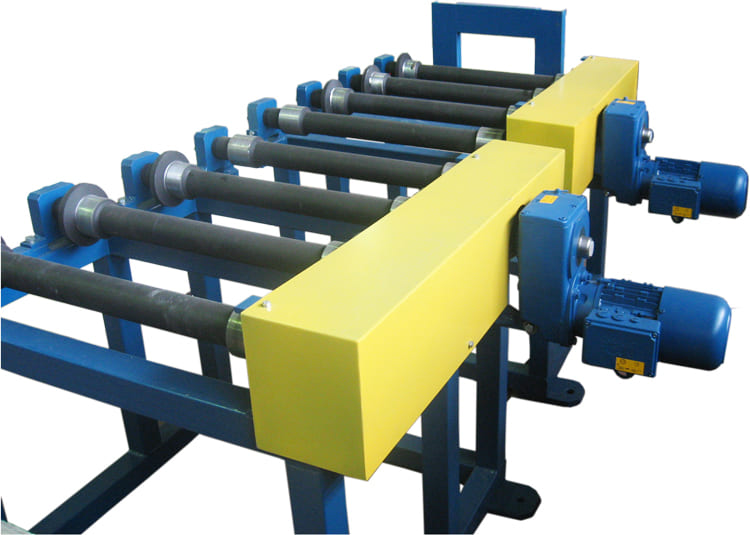

Design

The roller conveyor is a metal frame with transversely mounted rollers. Depending on whether the pins are connected to the drive elements, the rollers can be driven or non-driven. The driven roller tables rotate continuously or discretely and move the container, which rests on them. Non-driven ones are positioned at an angle to the horizon for the possibility of free rotation under the action of gravity of loads or other device, sometimes even manually. For a stable position, each product or container must simultaneously be supported by three more rollers. Therefore, the step is always selected according to the shortest workpiece or according to the permissible vertical load (in the case of massive slabs).

Frame it is welded from steel profiles in the form of a truss with supporting surfaces. At the bottom, the frame is fixed to the floor, and at the top there are guides for placing the bearing assemblies. To obtain the required length, the frames are connected at the ends, and the required height is set by the Customer during design.

Rollers consist of a central barrel made of a pipe with trunnions welded along the edges. The rows of rollers form a load bearing surface. Special flanges can be made on the barrels, protecting the workpiece or container from preventing movement in the axial direction and defining working size in width. Along the edges of the trunnion, they are supported by bearings with spherical bearings, which prevent axial displacement and allow free rotation.

Drive The rollers rotate from an electromechanical drive through a chain drive. Along the length of the conveyor, they are divided into several independent sections (groups) with their own gear motor. Frequency converters provide the required frequency and smooth rotation.

Limitations in application are the inability to transport bulk cargo without a container, to lift it to a height at an angle of more than 10 & # 176 ;. Roller bed versions are somewhat more expensive due to the greater complexity in manufacturing and a large number of drives.

The optimal ratio of dense refractories on the hearth and fibrous thermal insulation along the side walls increases it service life, minimizes heat loss by heat transfer and accumulation. Increased total thickness thermal insulation minimizes heat loss through the walls. Cast hearth plates made of steel no worse than 15Kh23N18L. Application of a direct mesh sprocket mounted on the drive and a rack rigidly mounted on the bottom eliminates jerking and coasting during start and stop.

(the territory of JSC "Ural plant RTI")