ELECTRIC LABORATORY OVENS

- Manufacturing of laboratory heating equipment

- Own design and production facilities

- Modern equipment and machines

ON ELECTRIC FURNACE

Baking cabinet for electrodes

Purpose and description

Annealing cabinet of the ShP-0.4-XX series is designed for drying and calcining welding electrodes up to 500 mm long, followed by long-term storage at elevated temperatures.

The cabinet can also be used for drying or calcining certain bulk materials, such as fluxes, or even for low tempering of small items.

Description of construction

Frame

The cabinet is formed on the basis of a steel welded frame, which consists of a frame structure in the form of a vertical truss with a door fixed on hinges. All inner and outer sheets, devices and accessories are attached to the body.

Heating chamber

The required temperature and convection are formed directly in the working space, where trays with blanks are placed. The chamber is formed by stainless steel sheets, in which there are ledges for the shelves and holes for the distribution of convection flows at different height levels. Pull-out lattice shelves with removable trays for electrodes up to 500 mm long are installed inside the cabinet. Each tray can accommodate up to 6kg of workpieces.

Thermal insulation

The space between the oven casing and the decorative panels is filled with several layers of basalt heat-insulating fiber mats. The layer of mats, facing inward, is made of mats foil on one side.

Convection

A fan stand with a centrifugal impeller brought out into the air channel is installed on the roof. The fan shaft is fixed in the bearing assemblies and rotates from the electric motor. The fan impeller draws air from the center and directs it to the side air ducts, where the air flow washes over the heaters, accumulates heat, and through a distributed system of holes is fed into the workspace. Due to the gaps between the trays and shelves, the flow is evenly distributed throughout the volume, transfers heat to the products and is sucked up to the centrifugal fan wheel.

Blowing

At the bottom of the rear wall there is a fresh air intake. In the area of the roof, a branch pipe is diverted from the fan level to discharge vapors and fumes from the working chamber.

The purge air volume can be adjusted with a valve on the exhaust pipe.

Door

The door frame is attached to the cabinet body through hinge joints. The inner door casing is made of corrosion-resistant sheet steel, and it fixes a cord seal around the perimeter. The inner space of the door is filled with basalt thermal insulation. The door handle is located on the left. Hole for optional reference thermocouple.

Heating control system

Power electrical equipment with control devices are mounted in a power unit, which is mounted on the left side wall and connected by consumers with cables with connectors. The thermodat, depending on the settings, can maintain the temperature according to the temperature-time schedule or maintain the set.

The necessary blocking of emergency and unacceptable situations has been implemented. To measure and control temperature, standard thermoelectric converters (thermocouples) of XA (K) calibration are used. The cabinet is delivered checked and adjusted.

All cabinets are offered for temperatures up to 400°C. C, with a supply voltage of 380V.

| Model | Volume in liters | Working dimensions (width×dl×height) | Overall dimensions, mm | power, kWt | Furnace weight |

|---|---|---|---|---|---|

| ShP-0,4-60 | 60 | 400×350×530 | 740×600×670 | 4,5 | 90 |

| ShP-0,4-140 | 140 | 535×800×625 | 1020×1600×900 | 9 | 220 |

| ShP-0,4-240 | 240 | 535×1350×625 | 1020×2000×900 | 11 | 300 |

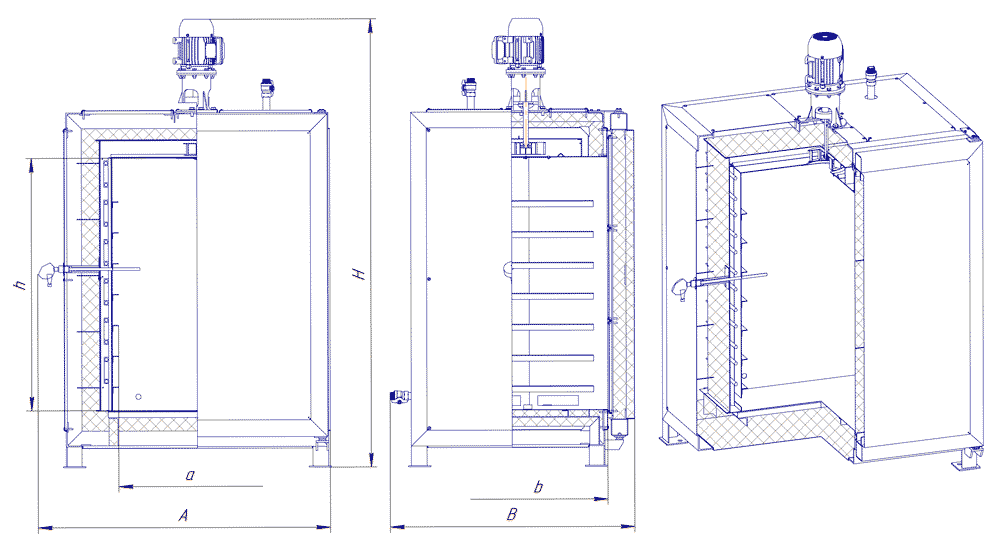

View design sketch

We offer a wide range of drying cabinets, including a specialized cabinet for drying electrodes with an optimal set of functions and capabilities, including those not reflected in this section. A wide assortment and diversified options allows our customers to purchase the optimal equipment for solving problems related to research, with high accuracy and reliability..

(the territory of OJSC "Ural plant RTI")